From the idea to the medical device: your partner for silicone innovation

Our technical experts design and manufacture finished, and semi-finished products meeting the health requirements and support you during all the steps of your project, in compliance with our quality management system.

Strategic silicone consulting

A dedicated project manager will help you choose the right materials and manufacturing processes to meet your device’s technical and regulatory needs. We also offer visual modeling to support a clear, collaborative development from concept to production.

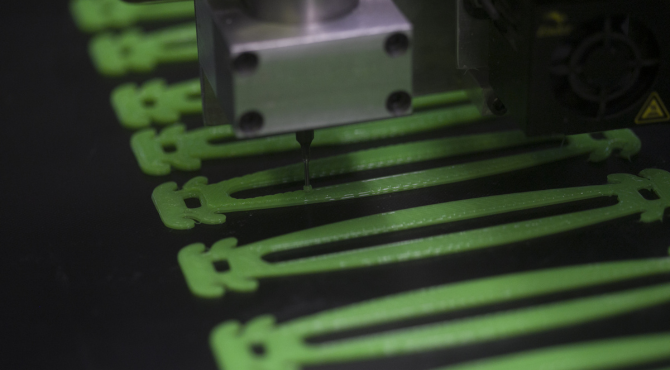

Rapid silicone prototyping

Our Fablab has developed in-house technologies for 3D printing: SiO-Shaping®. Rapid prototyping offers a reliable way to validate the technical feasibility of your parts early in the development process. This approach helps accelerate your time-to-market, reducing design iteration cycles, thus optimizing your costs.

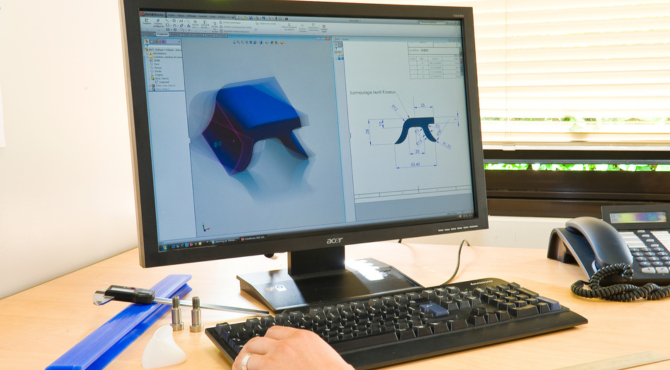

Tooling

The Final designs are created using SolidWorks® and seamlessly transferred to our in-house machining workshop. Without any intermediaries, we are more responsive and can reduce production times. Our workshop is equipped to design and retouch most of our production molds.

Production launch

Production is then completed in our certified cleanroom environments, ensuring high standards of quality, precision, and regulatory compliance at every stage.

Our know-how

Whether HCR (High Consistency Rubber) or LSR (Liquid Silicone Rubber), we master the transformation of platinum-cured silicone through a wide range of manufacturing processes tailored to your application.

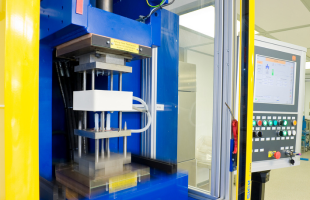

Molding and overmolding

We have a range of presses for molding and overmolding your high-precision technical parts, using injection or compression methods, suitable for small, medium, and large production runs.

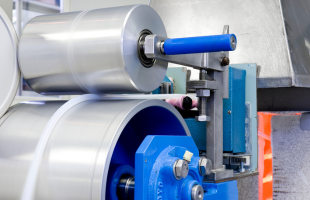

Extrusion and co-extrusion

Our extrusion lines enable us to produce profiles, tubes or cords, single or multi-lumen, and/or co-extruded.

Making

Our manufacturing workshop, combining manual know-how and technical expertise, is able to carry out gluing, cutting, vulcanization, deburring, tribofinishing, surface treatment…

Marking

We offer you the possibility to mark your medical device using several processes such as laser engraving, tampoprinting, UDI QR code marking…

Laboratory / R&D

Proactive and solution-driven, our laboratory is fully equipped to analyze your needs and deliver material and technical solutions tailored to your application.