In demanding environments such as floating wind or Oil & Gas, every material must combine reliability, high resistance, and long-term durability. This is why the EXSTO Group developed ELADEEP®, a range of high-performance polyurethanes, which has notably been implemented in the LAPA project.

A formulation designed to withstand Subsea challenges

The ELADEEP® polyurethane range includes four grades:

- ELADEEP® E950 (95 ShA) and E980 (98 ShA) for Bend Stiffeners

- ELADEEP® E82HT (82 ShD) and E85HT (85 ShD) for Bend Stiffeners

Specifically formulated for subsea applications, these polyurethanes offer unique technical properties:

- Exceptional hydrolysis resistance, ensuring long-term stability and durability under prolonged immersion.

- High fatigue resistance, enabling the material to absorb repeated mechanical stress without degradation or risk of failure.

- Transparency (E950 and E980), allowing easier visual inspections, which is critical to detect defects and minimize risk.

All materials in the ELADEEP® range are tested according to the industry’s most stringent standards to ensure exceptional reliability and performance. The range has received TAC (Type Approval Certificate) certification in accordance with API17L standards.

Today, ELADEEP® polyurethanes are considered a reference both in the floating wind and Oil & Gas sectors.

ELADEEP® rising to offshore challenges

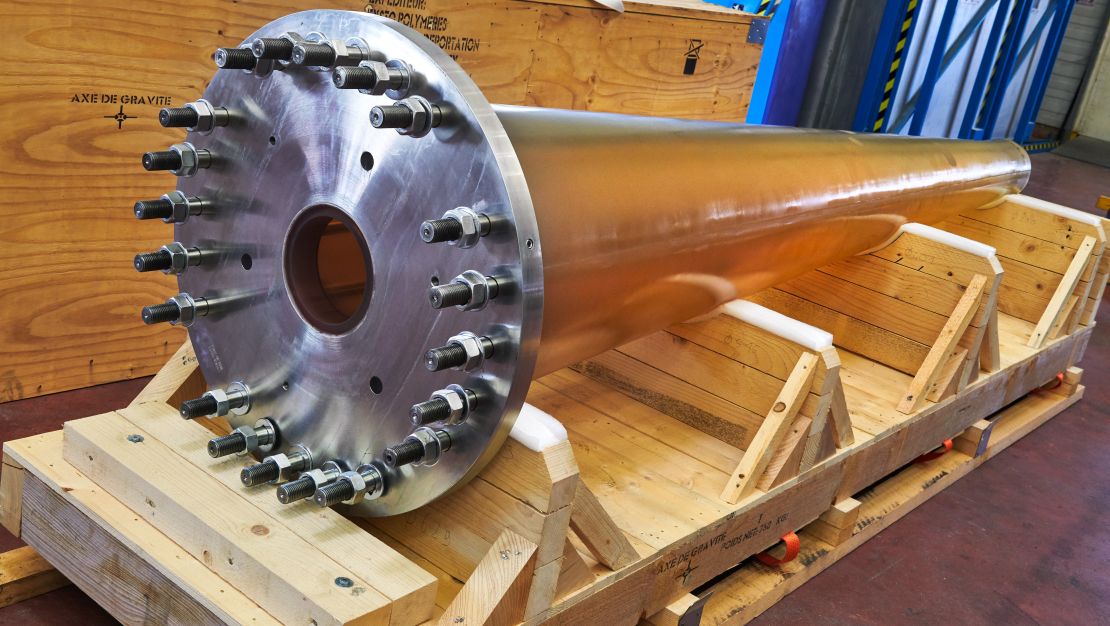

ELADEEP® E980 was used for the LAPA project, leading to the manufacture of three Bend Stiffeners. This technical feat called on EXSTO team’s advanced expertise in tooling and moulding processes, demonstrating the Group’s ability to meet challenging demands.

In parallel, two Bend Stiffener Connectors were produced by EXSTO Brasil, highlighting the synergy between the Group’s international sites. This global organization enabled controlled delivery times and close client collaboration, all while maintaining the highest quality standards.

The successful delivery of this project once again confirms ELADEEP® polyurethanes’ reliability and performance in demanding offshore conditions.

By designing subsea cable protection solutions using ELADEEP® polyurethanes, EXSTO is redefining the standards for subsea materials. Combined with its international presence, EXSTO helps secure energy infrastructures while ensuring long-term performance.

With EXSTO, protect your cables to safeguard the future.